Table of Contents

Summary

Depending on where the spot weld symbol is in relation to the reference line, it may or may not mean something on the arrow side or the other side. Dimensions must be shown on the same side of the reference line as the symbol or on either side if the symbol is in the middle of the reference line and doesn’t mean anything by being on the arrow side or the other side. The name of the process is shown at the end of the welding symbol. Then projection welding should be used. The spot weld symbol should be used, with a reference to the projection welding process at the end of the symbol. The spot weld symbol must be in the middle of the reference line, either above or below it.

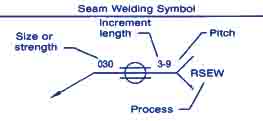

Seam welding symbol

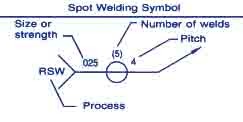

spot welding symbol

Size Of Arc Seam And Spot Welds

- Size or strength can be used to measure these welds.

- The diameter of an arc spot weld must be used to describe its size. The width of the weld should be used to describe the size of an arc seam weld. Dimensions will be written as fractions or decimals in hundredths of an inch and shown to the left of the weld symbol, with or without inch marks (A, fig. 3-38).

- The strength of arc spot welds must be given in pounds or newtons per spot. This is the minimum shear strength that can be used. The strength of arc seam welds is given in pounds per linear inch. To the left of the weld symbol, you can see the strength (B, fig. 3-38).

Arc Weld Symbols with Arc Spot and Arc Seam Weld Dimensions

How far apart arc spot welds and arc seam welds are:

To the right of the weld symbol, the pitch (center-to-center spacing) of arc spot welds and, when given, the length of arc seam welds must be shown (C, fig. 3-38).

When spot welding or arc seam welding goes the whole distance between sudden changes in the direction of welding, the welding symbol doesn’t need a length measurement.

Extent And Number Of Arc Spot Welds And Arc Seam Welds

When arc spot welding goes less than the distance between abrupt changes in the direction of welding or less than the full length of the joint, the extent must be measured (fig. 3-39).

Symbol for Arc Spot Welding Arc Length

When a certain joint needs a certain number of arc spot welds, the number must be written in parentheses above or below the arc weld symbol (fig. 3-40).

Number of arc spot welds in a joint represented by a symbol

On a drawing, a group of spot welds can be found where two center lines meet. The arrows point to at least one of the center lines that goes through each place where a joint was welded.

Welded joints with a flush arc spot and an arc seam

Arc-seam and flush-arc-spot weld joints. When the exposed surface of one member of an arc spot or arc seam welded joint is to be flush, that surface must be shown by adding the flush contour symbol (fig. 3-41), just like for fillet welds.

Symbol for Arc Spot and Arc Seam Welds Surface Contour

Arc seam welds: the deets

The welding symbols can’t show how far apart arc seam welds are, how big they are, how they are oriented, or where they are. The drawing must show this information.