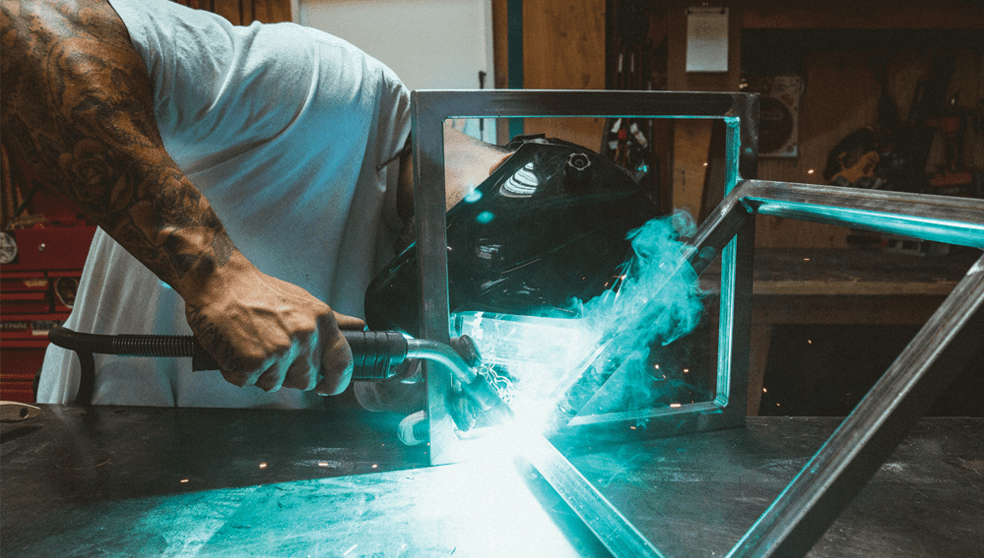

Welding is a valuable skill to have. There are several types of welding – each with their own advantages and purposes. If you are a newbie, it is a good idea to start with MIG welding. MIG stands for Metal Inert Gas welding. This is perhaps the easiest kind of welding. So, you will learn it soon.

Table of Contents

How is it done?

MIG welding is a process that melts and joins metals. Here, you use an arc of electricity and create a short circuit between the piece of metal and the welding gun. The short circuit, along with the inert gas, produces enough heat to melt the metal pieces.

A few tips to get started

Safety should be your top priorityWelding, whether professional or as a hobby, carries its set of risks. When there is electricity, gases, and high temperature involved, it is good to be safe than sorry. Wear protective equipment for safety.

This includes goggles/a helmet, closed shoes, gloves, and clothes made of safe material. Synthetic clothes can easily catch fire. Thus, flame-resistant clothes are preferred.

Check your connections twice

There are several connections you need to set up.

- You need a source of power supply

- Connect the metal piece to the power supply using a work clamp

- Next, you need a functional welding gun

- Finally, use a gas shield

Keep your workspace free from debris. Adjust the gas flow, wire feed speed, and voltage as per your need.

Choose an appropriate shielding gas

Carbon di Oxide and Argon are 2 commonly used gases in MIG welding. Your choice of gas depends on your budget and wire material. For instance, if you are using stainless steel wire, a mix of Argon, C02, and Helium is a good choice.

For Aluminium wires, Argon is the preferred shielding gas. Thus, know which gas will best suit your wire.

Have a clean surface

The piece of metal that you are going to weld should be as clean as possible. It could be covered with rust, paint, or may have even scaled off. This must be taken care of before welding. Sanding disks or non-woven abrasives can be used for the purpose. This is important and will help you obtain a clean finish.

Do a practice round

If you are not sure about your technique, use a piece of scrap metal to test it. Rather than starting with the actual metal, it is better to experiment on a scrap piece and go ahead if you are familiar with the technique.

If the end product is smooth, your method is right. If not, look for possible errors – the wire speed, the power settings, the sound you hear, shielding gas, the distance between the gun and the weld.

MIG welding has a bunch of advantages such as ease of learning, less splatter from the weld, supports all-position welding, and can be used on a wide range of metals. Using the tips given above, start a new hobby today!